There are a variety of gearbox specifications for each machine or motor that may increase torque output via gear reduction. To ensure the greatest performance, it is important to compare characteristics before making a decision. It’s not uncommon to see both worm and bevel helical gears utilized in diverse industries. Check out this quick guide to ensure you have the necessary torque and power transmission.

Worm Gears Definition

It’s a type of gear system where the worm (screw) meets a gear, which is a worm gear. The client has complete control over the speed of this kind of equipment because of the special materials used in its construction. Additionally, worm gears may be employed to boost torque.

The worm can turn the gear; however, the gear is unable to do so and turn it. This idea indicates self-locking. A common use for worm gears is in high-speed reduction gearing. Implementations including conveyor systems, in which the locking mechanism functions as a brake, are common. Worm gears are often utilized in various applications. Besides that, they are frequently used to calibrate instruments, lifts, and gates.

To improve the effectiveness of industrial gear systems, it is important to understand the differences between worm and helical gears and their advantages and disadvantages.

Bevel Helical Gearbox Definition

Helical bevel gearboxes are angular gearboxes where the output shaft of the gear unit turns 90 degrees in reference to the rotor shaft of the motor. Solid or hollow shafts are typical.

Gearboxes with helical bevels, which may provide high power density and output torques, are appropriate for angular geared motor applications that need high power density and output torque.

Bevel helical gearboxes are often employed in baggage conveyors, rope lifters, and industrial mixers because of their small size and great power density.

Stable power and energy transmission are made possible by the teeth being engaged.

The Three Differences Between Worm And Bevel Helical Gearboxes

Working mechanism

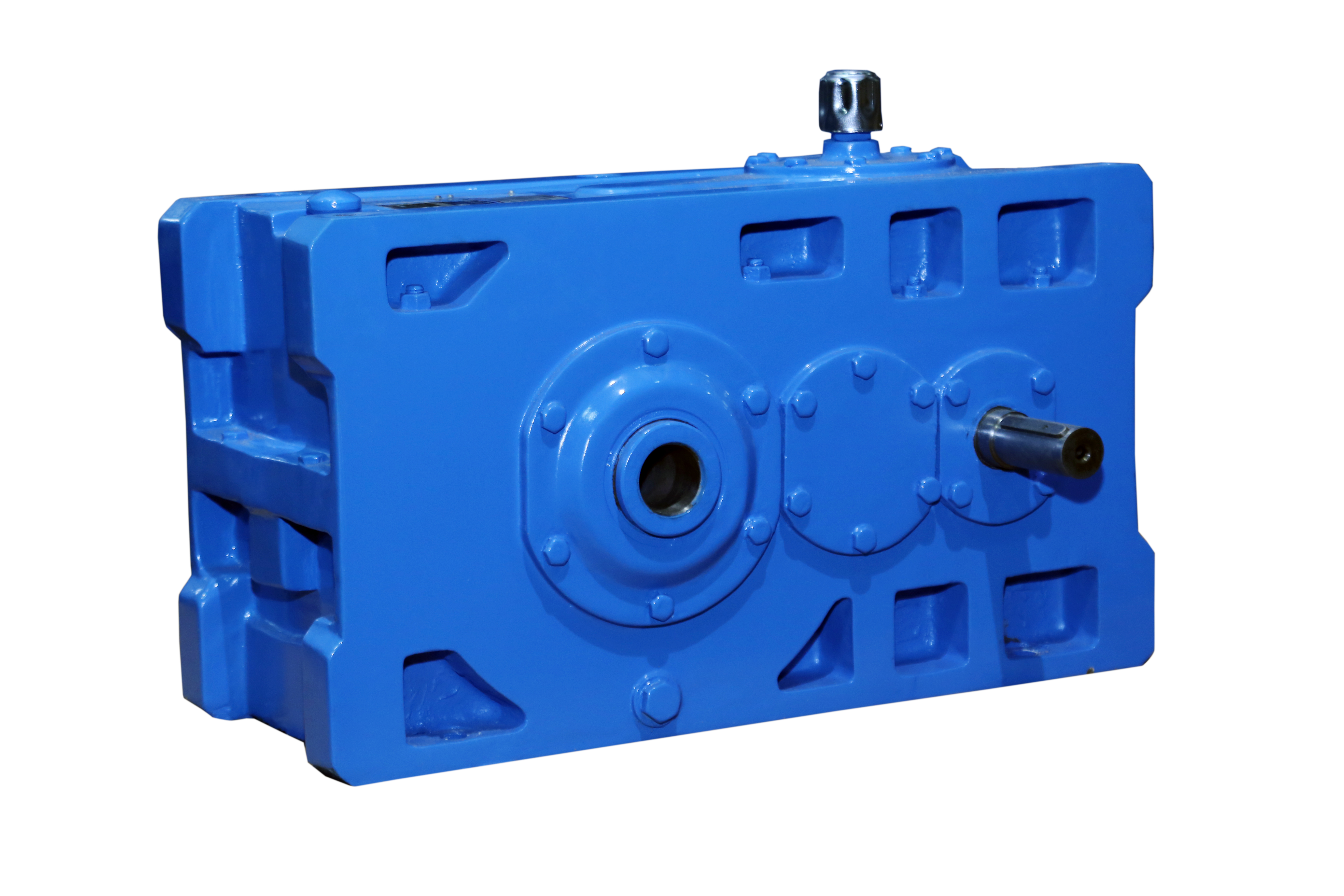

Worm Gearbox

This gearbox utilizes a big diameter worm wheel that links to the teeth on the worm shaft perimeter. The engine generates rotational energy through the non-intersecting & perpendicular axis of the worm wheel. Due to the fact that the meshing gears travel through one another, they might result in a significant drop in speed, which is advantageous for a wide variety of applications.

Bevel Helical Gearbox

A distinguishing characteristic of bevel helical gearboxes is that their curving teeth are contained inside a cone-shaped base at the device’s edge. This design generates rotational motion between non-parallel shafts, resulting in a quiet and sturdy functioning.

Applications

Worm Gearbox

The chemical and fertilizer industries are prominent users of worm reduction gearboxes. Worm gearboxes are also advantageous for shock-loading applications. This category covers heavy-duty devices such as crushing equipment, packing equipment, and conveyor belts. Additionally, worm gearboxes may be used in situations where noise is an issue. The sliding movements are more silent, which is advantageous for building airports, theatres, and elevators.

Bevel Helical Gearbox

These gearboxes are well suited for applications requiring a high torque output and good efficiency ratio. Additionally, they are configurable. Concrete, steel, plastic, automotive, and minerals are just a few of the sectors that rely on this industrial gearbox for its durability and heavy-duty applications.

Power Transmission Capacity

Gearboxes’ primary function is to transfer torque, mechanical energy, and mobility from one location to another. As a result, it is prudent to assess both power transmission options’ power transmission capabilities.

Worm Gearbox

Worm Gearboxes are renowned for their low-power, low-speed applications. However, it has limited capability for power transmission.

Bevel Helical Gearbox

The Bevel Helical Gearbox enables a wide variety of applications. They have a better capacity for power transfer than worm gearboxes. Additionally, bevel helical gearboxes have a high ratio of efficiency.

Conclusion

Now that you are aware of the distinct qualities of both industry gearboxes, it is critical to choose the one that is most suited to your business’s needs. Due to technical improvements, gearboxes can now handle the demanding power transmission requirements necessary to reach the specified output speed. By contacting us at Premium Transmission, a reputable gearbox manufacturer , you may get further information about their specifications and features and make an educated purchase.