Industrial Gearboxes are used in a various small scale and large-scale Industries and find a wide range of applications. Premium transmission is a leading Industrial Gearbox manufacturer in India. They specialize in the manufacturing of Industrial gearboxes like Helical Gearbox, Planetary Gearbox, Worm Gearbox & Geared Motors.

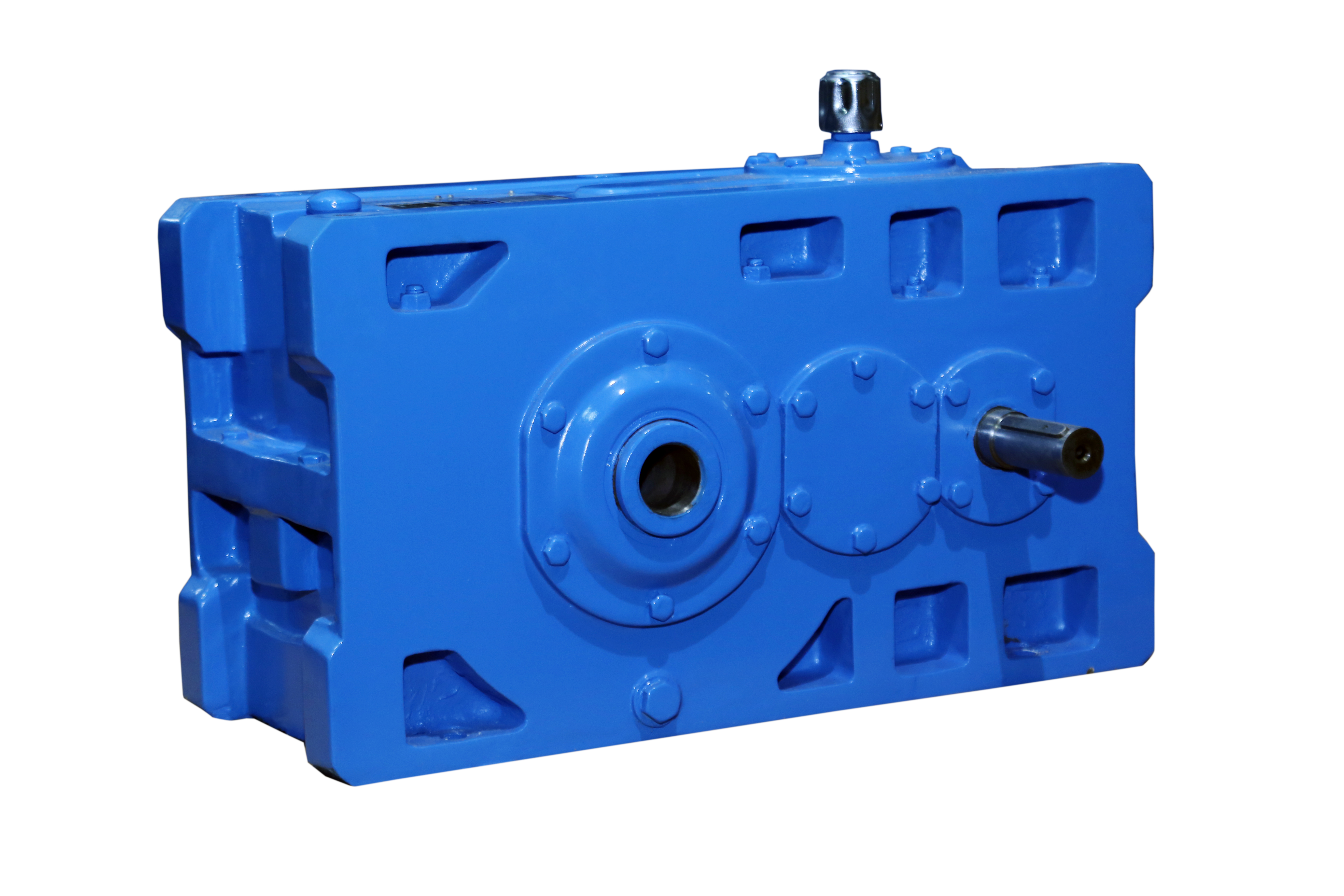

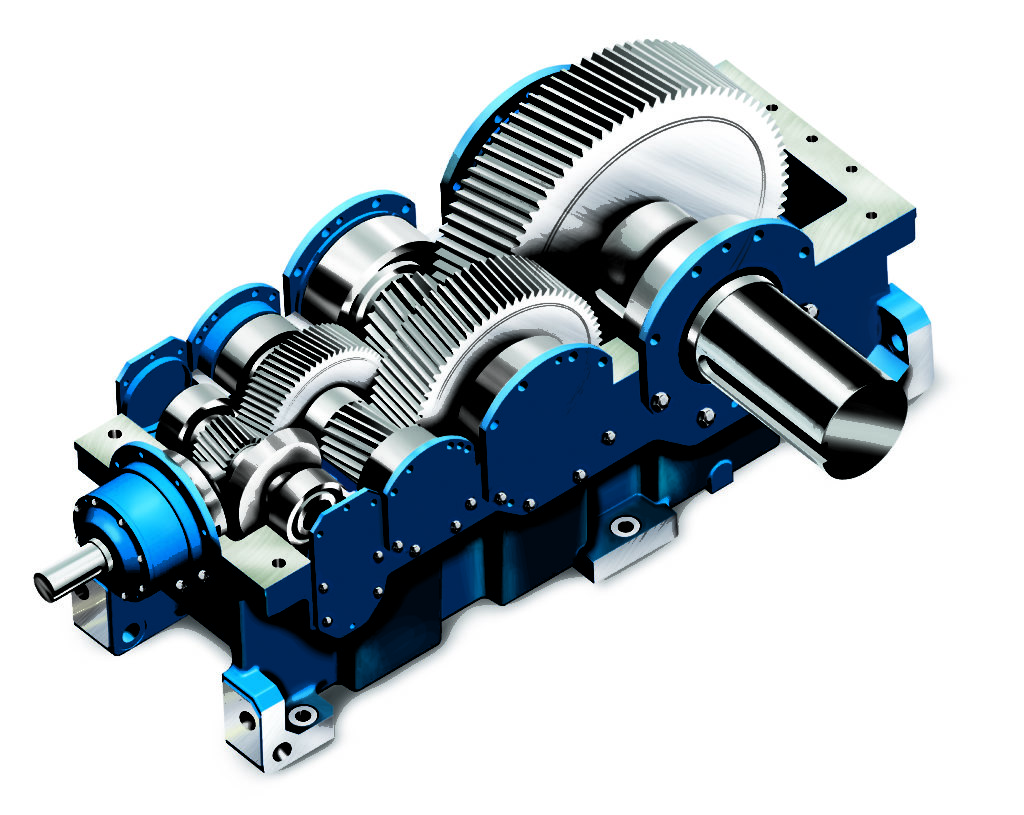

Helical Gearbox– Helical gears have teeth that are oriented at an angle to the shaft. This leads to more than one tooth to be in contact during the operation, which makes the gear capable of carrying more load. Due to the load sharing between teeth, this arrangement also allows helical gears to operate smoother and quieter than spur gears.

The modular design and construction of the Helical Gearbox offers several engineering and performance benefits, including a high degree of interchangeability of parts and sub-assemblies. This provides for an economical production, while maintaining the highest standard of component integrity.

Helical gearboxes are one of the most vastly used gearboxes and are more efficient than any other Gearbox. Their arrangement facilitates many operations.

According to their need for applications in different industries there are different modifications of Helical Gearboxes.

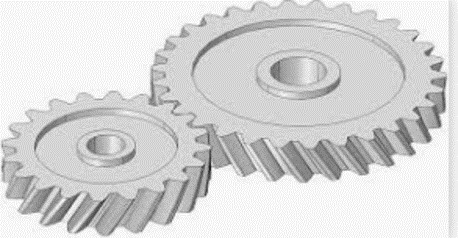

- Single Helical Gear

Single helical gears are the gears that are at a certain angle to the axis. You can have left and right hand orientation of the gears. The main characteristic of the gear is getting more surface contact and load carrying capacity.

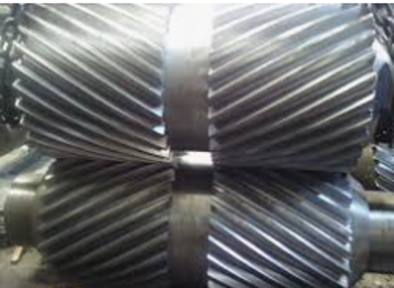

- Double Helical Gear

Double helical gears are a variation of helical gears, in which two helical faces are placed next to each other with a gap separating them. Each face has similar but opposite, helix angles. Employing a double helical set of gears eliminates thrust loads and offers the possibility of greater tooth overlap and smoother operation.

Like the helical gear, double helical gears are commonly used in enclosed gear drives.

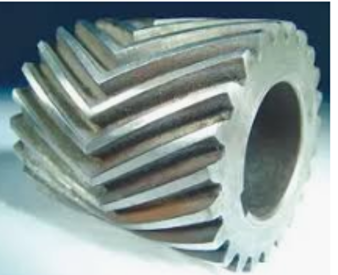

- Herringbone Gear

Herringbone gears are similar to the double helical gear, but they do not have a gap separating the two helical faces. Herringbone gears are typically smaller, and are ideally suited for high shock and vibration applications. Herringbone gearing is not used very often due to their manufacturing difficulties and high cost.

Why Helical Gears?

- The angled teeth engage more gradually than spur gear teeth so that they can run more smoothly.

- Helical gears, as well as Helical Gearboxes, are highly durable and ideal for high load applications.

- It has the capacity to transmit motion and power between either parallel or right-angle shafts.

Helical Gearboxes are the most efficient gearboxes manufactured in the industry and work at 98% efficiency just after Planetary Gearboxes.

The overall application of helical gears and helical gearboxes are widespread.

Helical Gearboxes are used in the following Industries:

- Fertilizer industries, printing industries, and earth-moving industries

- Steel, rolling mills, power and port industries

- Textile industries, plastic industries, food industries, conveyors, elevators, blowers, compressors, oil industries & cutters.

In Addition to the above, they also find applications in crushers, extruders, coolers, cranes, mixers and conveyors, which are all low-power applications.

At Premium, we ensure high quality at every stage of manufacturing process to meet the best standards. We are one of the leading Industrial gearbox manufacturers in India with a state-of-the-art manufacturing unit.

Premium Transmission has an in-house R&D facility that has received approval from the Government of India. We provide power transmission solutions across industries. Our team of experts understand the requirements of customers and bring tailor made solutions that are specific to their needs.

Contact Premium Transmission for your mechanical power transmission requirements