Choosing the proper coupling for the job at hand requires asking the appropriate questions before defining a certain form. Choices abound, and with more than one form of coupling can be ideal for any given use.

In this blog, we’ve covered certain pointers you should look for while choosing the right coupling from your manufacturer in India.

1. Don’t Let Habit Or Price Be A Determining Factor

Often companies make selecting a coupling style a matter of having used the same style for a previous project. However, since not all couplings are formed on an equal level, it is always out of the experience that the equipment has to be combined with coupling capability. Another cause of the error is the option of coupling based on price rather than output criteria. Driven to reduce the cost of machinery, engineers can shorten the application by being excessively thrifty in their choice of coupling. Although this strategy can minimise the initial expense of parts, lengthy and costly backend warranty lawsuits can harm the bottom line of the OEM and the credibility of the commodity.

2. Identify The Right Way To Mount The Coupling On The Shaft

The system by which the coupling is mounted on the shaft can decide the success or failure of the coupling, regardless of whether the coupling is suitable for operation. Common buttons, keyways, and taper bushes perform well in unidirectional implementations with limited shock or reversing loads. Keyless locking systems are the ideal mounting system for reversing loads and shock installations since keyless systems are backlash-free. For example, the mounting of a torsionally stable, backlash-free, high-speed disc coupling with a keyway and a set-screw negates the backlash-free nature of the coupling. A keyless locking mechanism would help fulfil the intended function of the coupling. On the other side, the mounting of an extremely flexible jaw coupling with a keyless locking mechanism may be overkill based on the rough and flexible design of the coupling type.

3. Determine The Requirement Of The Coupling

Perhaps the most important thing is to ask yourself, “What does this coupling need to do? “Other questions are: does it need to send a high or low torque? Is the operation at high or low speed? Do you need to be maintenance-free? How about a free backlash? Are there any misalignments between the elements to be paid for, and for how much? Will the programme need coupling in order to withstand the shock? How significant is the cost? What’s the weight? What regarding environmental conditions, such as air temperature, humidity and corrosion? Knowing the answers to these questions with respect to the application and cross-referencing of the relevant couplings will help in the identification of the most appropriate coupling for the application. Remember: more than one form of coupling can work.

4. Learn The Right Terminology

Inch-pounds or inch-ounces? It may seem simple, but the units of the torque rating of the coupling are always mistaken. Having the spec wrong will make you skip the correct coupling option by more than an order of magnitude. Another source of misunderstanding is the use of keyways: Keyway couplings are high torque, not high precision. If the application involves reversing torques or direction plus accurate alignment between the driving and the driven shafts, the keyways are not suitable. Instead, coupling with set screw or clamp-like hubs is the perfect option for precision applications. One more note — if you need zero backlashes, get zero backlashes. Many forms of couplings, like flexible bellows shaft couplings, do not allow backlash, although other styles cause some backlash to occur.

5. Proper Installation Is Crucial

Choosing the best pairing for an application can be a dynamic operation, but it doesn’t take too much time. The best approach is to pay due attention to all the design requirements. Usually, this involves pressure, shaft misalignment, stiffness, RPM, inertia, volume requirements, and shaft mounting. At the end of the day, a coupling that solves all these issues would work as needed in the application.

With our extensive guide, selecting the right coupling could not have been easier! Just follow the recommendations mentioned in this blog and you will surely find the highest quality coupling that will last for years. You can also use our Configurator “PRoCon” for selection of right coupling for all your needs and applications.

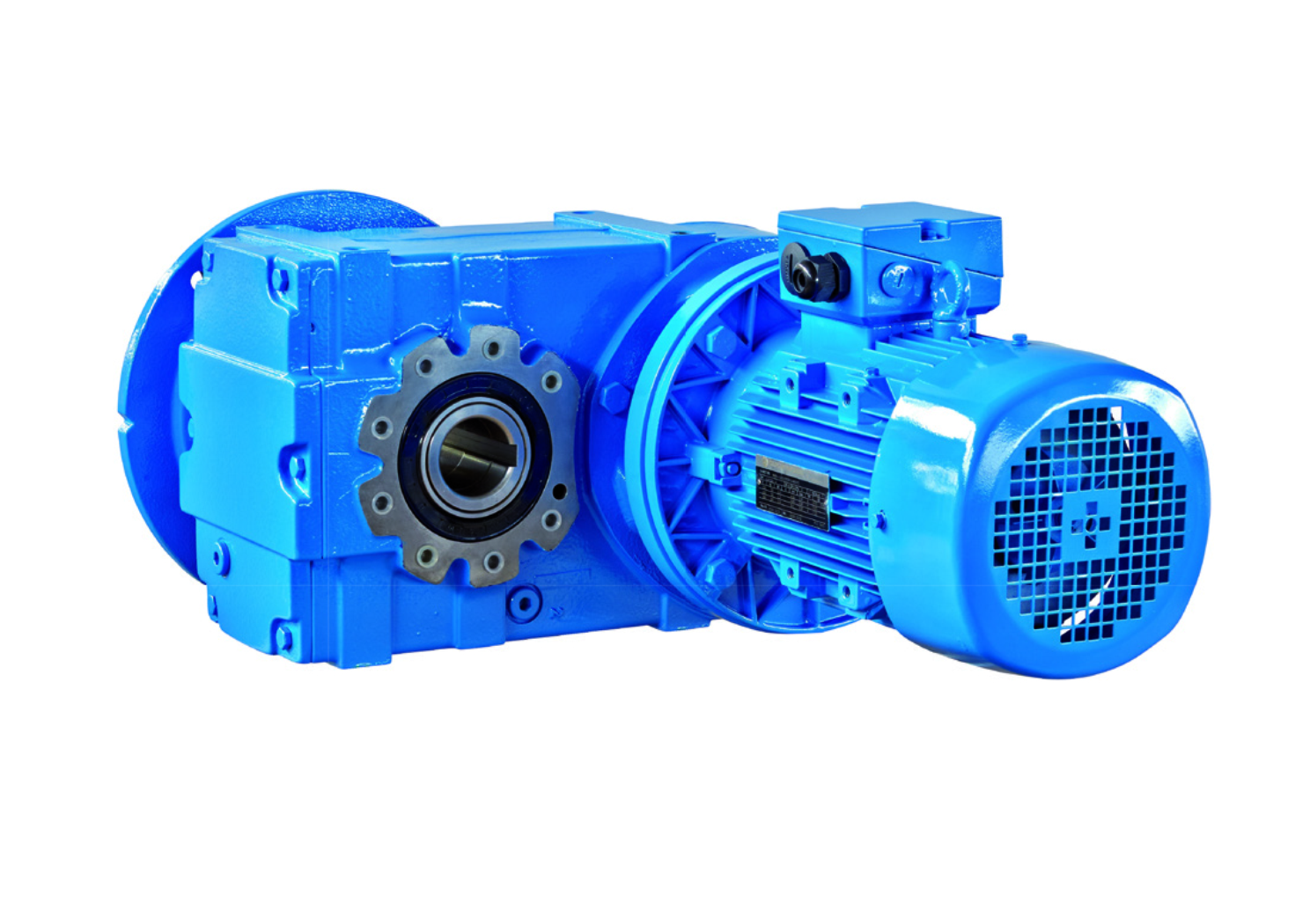

If you are looking for the best Fluid couplings and gearboxes as a complete power transmission drive unit, you can reach us at Premium Transmission and our team of experts will readily help you!