Are your gears slipping or is your clutch making a crunching type of noise? Experience one of the two, and you could find yourself worrying that an expensive gearbox failure is imminent.

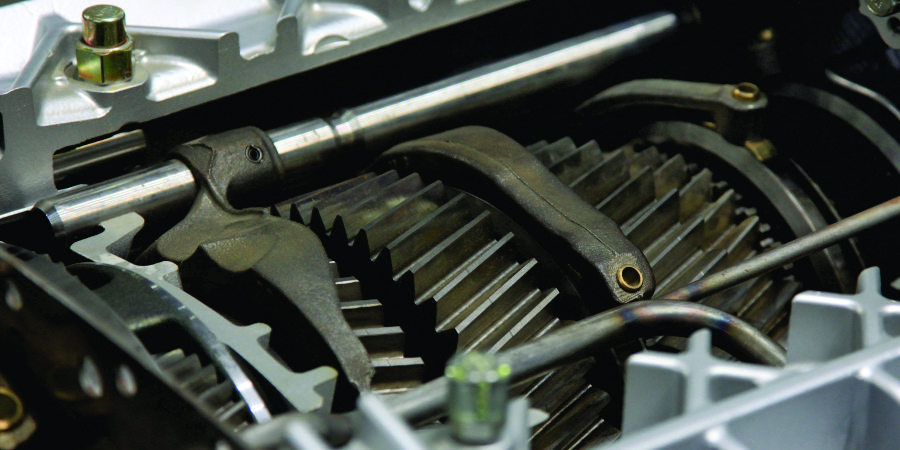

A gearbox failure can create quite a problem on the long run. Machinery breakdowns are generally the reason for gear failure. Premium is one of the well-known Gear Manufacturing Companies in India and is focused towards building quality products through its robust processes and system in all plants. We manufacture a wide array of Power Transmission Gearboxes such as Helical, Bevel-Helical Gearboxes, Worm Gearboxes and Planetary Gearboxes that are manufactured at our state of the art manufacturing unit using high-quality raw material that is sourced from some of the most trusted and reputed vendors of the market.

Our highly trained experienced staff, pays close attention to maintenance practices and checks for inferior repairs.

Gear failure can stem because of many reasons but is mostly caused due to the most ordinary issues. The most common factor is exceeding the life expectancy of a gearbox, leading it to wear and tear due to extensive usage.

The Major Areas Where Gears Tend to Fail are:

-

- Shock loading failures

- Fatigue Failures

- Failures due to Wear

- Failures due to scuffing

- Shock Loading- caused due to sudden shock loads: When a gear system is subjected to a load it is not designed to bear, it results in breakage. There is no way to identify this beforehand, but utmost care needs to be taken to avoid such mishaps.

- Fatigue failure

-

- Bending fatigue- fatigue occurs over time in response to repetitive loading. Due to the application of load, the gear tooth is subject to bending leading to fatigue. The fatigues in the gear cause the formation of cracks in the root of the gear tooth, leading to the failure of gear tooth.

- Pitting or Contact Fatigue- 60% of gear failures are caused by Pitting. The formation of craters on the gear tooth surface is called Pitting. The crater formation occurs due to high compressive contact stresses in the gear surface occurring due to compressive fatigue on the gear tooth surface.

- Micro Pitting – is formed due to the presence of water in the lubricant, that is responsible for lubricating the gears; wrong viscosity selection of the lubricant used. Apt to the name micro pitting is hard to find, they appear as tiny dots, and one has to study the surface of the gear tooth to find the Pitting.

- Fatigue due to Wear- tooth wear can occur in three categories- abrasions, adhesions, polishing. In abrasions, gear tooth wear occurs due to the contaminants in a lubricant. In adhesions, foreign particles attach themselves to the tooth. Polishing is another minor type of abrasion. Gear wear can range from mild to severe, depending upon the intensity and nature of the gear’s movement.

- Failure due to Scuffing –occurs when metal from one gear tooth transfers to another over time. It is also a severe type of adhesion.

Some of the other reasons for Gear failure are:

- Frosting – Frosting happens when the lubricant film breaks down due to excessive heat. The tiny pits that appear outside the gear are due to this factor. It is necessary to keep a check on temperature to avoid this.

- Particulate contamination- Can be from putting dirty oil in, leaving a filling plug open or from wear or failure particles within the gearbox. Not only can this be an indicator of problems within the gearbox itself but the particles can also accelerate wear and component breakdown.

- Handling and installation can cause component failure. This applies in particular to bearings where the cages are particularly prone to careless handling, installation or removal, but can equally apply to misaligned shafts which can then lead to bearing or gear failure.

Gear failure cause statistics:

- 34.4% – Inadequate lubrication

- 19.6% – Contamination

- 17.7% – Installation errors

- 6.9% – Overload

- 2.8% – Handling errors

Premium transmission is a renowned Transmission Gear Manufacturing Company in Pune, also known for exporting and supplying exclusive range of Gearboxes of optimum quality.

At Premium, the product quality has been ensured at each stage of the manufacturing process to meet the best standards.